Whether developing or manufacturing components for batteries, supercapacitors or fuel cells, Carestream can add value to your energy storage systems. We combine our simultaneous, multilayer coating expertise with analytical lab, small-scale pilot and production coater assets to deliver a variety of process development advantages including reduced up-front capital investment costs and efficient scale-up of energy storage products to commercialization.

Whether developing or manufacturing components for batteries, supercapacitors or fuel cells, Carestream can add value to your energy storage systems. We combine our simultaneous, multilayer coating expertise with analytical lab, small-scale pilot and production coater assets to deliver a variety of process development advantages including reduced up-front capital investment costs and efficient scale-up of energy storage products to commercialization.

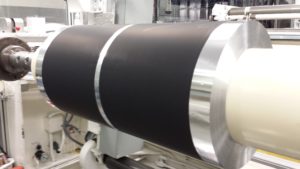

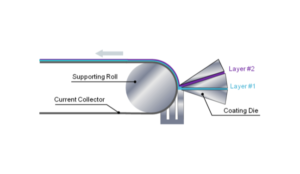

Leveraging over 100 years of precision coating leadership due to our 3M/Kodak history, we seek partners with whom Carestream’s unique expertise can be applied to the development of multilayer lithium-ion battery constructions. Our simultaneous, multilayer coating process enables the addition of multiple coated layers without additional passes through the coating machine – resulting in improved performance and reduced cost of battery products. Potential constructions through multilayer design flexibility customers include:

Carestream provides project-ready coating facilities in the United States featuring lab, pilot-scale and full production assets, and manufacturing excellence, with supply chain and finishing services in Asia, to deliver demanding, precision-coated battery structures. Our partnership agreements include: joint development, manufacturing partnership on customer assets and/or ours, and full joint venture. We also leverage our established relationship with Polaris Battery Labs to help customers overcome common roadblocks of bringing their product inventions to market.

Carestream Multilayer Coating Capabilities

Carestream successfully passed the CTIA Battery Certification Program, which validates a lithium-ion battery’s compliance with the IEEE Standard for Rechargeable Batteries for Cellular Telephones (IEEE Std 1725™ – 2011) and the IEEE Standard for Rechargeable Batteries for Multi-Cell Mobile Computing Devices (IEEE Std 1625™ – 2008).

For more information, contact Robert Wildman to discuss how a Carestream partnership can increase your energy storage success.