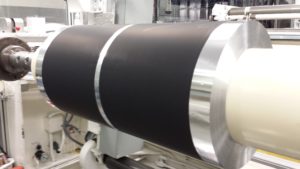

Precision Multilayer Coating and Manufacturing Capabilities

Carestream’s precision, multilayer coating operations provide efficient scale-up from product development to commercial scale, including technology development collaboration, fluid and coating engineering for manufacturing, and process design and implementation. Backed by exceptional Lean Six Sigma manufacturing practices, our engineers apply deep knowledge and unique analytical capabilities to identify and develop optimal coating solutions to meet partnership requirements, with planning, logistics, finance and purchasing competencies available.

Carestream multilayer coating and process development capabilities include:

Precision, Multilayer Coating

Technologies:

Technologies:

- Single and simultaneous multilayer coating

- Slide (cascade) and curtain multilayer coating

- Slot die, dual slot die, roll, gravure, knife, etc.

- Proprietary techniques

Solutions and Slurries:

- Aqueous

- Solvent (MEK, IPA, NMP, Acetone, Toluene, Methanol, Heptane, and many other solvents)

Substrates:

- Film

- Paper

- Foil

- Non-wovens

Substrate Thickness:

Substrate Widths:

Line Speeds:

* Capabilities are dependent upon which coating asset is utilized

Pilot and Production Coating and Development

Pilot Capabilities:

Pilot Capabilities:

- Widths from 100 to 300 mm, speeds from 1 to 60 mpm

- High-efficiency multi-zone drying up to 190° C

Production Capabilities:

- Widths from 600 to 1,470 mm, speeds from 15 to 150 mpm

- Two coating stations – one or both sides

- 1 to 8 layers in single pass

- 3 to 6 zones drying up to 150° C and 425 m of drying path

Pilot and Production Capabilities:

- Solvent and aqueous solutions

- Temperature-controlled solutions and coating

- CDT, web cleaning, UV curing, lamination

- 100% optical inspection to 25 micron resolution

- Real-time process control and feedback and analysis

- Variety of coating technologies (slot die, slide, curtain, gravure, etc.)

- Highly uniform < 2% to 5% thickness variability

- Class 100 clean room capable coating and web path

- Slitting capabilities

Solution Making and Delivery

Solution Making:

Solution Making:

- Stainless steel mix tanks

- Capacities of 175 to 6,500 L plus portable pilot tanks

- Nitrogen inerted and jacketed with heating and cooling

- Variable speed agitation with multiple blade types

- Particle dispersion via multiple high-shear options

- Bulk solvent storage and DI water generation

- Recipe control and robust standard work

- Distributive control system with data historization

Solution Delivery:

- In-line mixing and filtering

- Closed-loop mass flow control

- Variety of pumping options

- De-bubbling

- Process verification (T, P, flow rate, level control, etc.)

- Overhead lines with filtration direct from solution making

- Pails, drums or totes at the coating station for small-volume experiments and production

Quality and Analytical Testing

On-Line Inspection and Instrumentation:

On-Line Inspection and Instrumentation:

- On-line scanning capabilities to inspect coatings, both in reflection and transmission

- Full scanner implementation on pilot coater to support development

- Fully instrumented pilot and production processes with high-speed data acquisition and historization

Test Equipment:

- Optical Microscopy

- Scanning Electron Microscope (with EDX)

- Atomic Force Microscopy (AFM)

- High-Performance Liquid Chromatograph

- X-Ray Fluorescence Spectrometers

- Gas Chromatograph with Mass Spectrometer

- Thermogravimetric Analysis – Fourier Transform Infrared Spectrometer (TGA-FTIR)

- Optical Profilometry

- Inductively Coupled Plasma Spectrometer

- Dynamic Scanning Calorimetry

- Dynamic Mechanical Analysis

- Ultra-Violet / Visible Spectrometers

- Microtrac Particle Size Analyzer

- Microtome

- Titrations

Test Properties:

- Thickness / Uniformity / Coat weight

- Viscosity / Density / % Solids / Surface tension

- Cosmetics (streaks, point defects, etc.)

- Peel force / Adhesion

- Retained solvents

- Porosity / Density

- Particle size

- Roughness

- Contact angle

- Moisture analysis

- Conductivity / Resistivity

Converting and Packaging

Converting:

Converting:

- Film and paper converting

- Roll and sheet converting capabilities

- Web inspection available

- Experience with a variety of support types and thicknesses

- Controlled atmosphere conditions

- Safe lighting available

- Fully automated to manual range of automation

- Customized to customer requirements

Packaging and Shipping:

- Experience with a large variety of packaging requirements

- Variety of formats including bag, cartridge, box, sleeve and case

- Expertise in domestic and international shipping; including full loads, LTL and ocean containers

- Worldwide regional locations near your customers

Rapid Prototyping

Carestream’s highly flexible coating assets, combined with our experienced technical and business teams, enable rapid material and product screening, small product sample coating and testing, and efficient scale-up to pilot and production coating equipment. We work with our partners to quickly adjust formulation and coating conditions for low-cost, small-run and experimental multilayer coating projects.

Carestream’s highly flexible coating assets, combined with our experienced technical and business teams, enable rapid material and product screening, small product sample coating and testing, and efficient scale-up to pilot and production coating equipment. We work with our partners to quickly adjust formulation and coating conditions for low-cost, small-run and experimental multilayer coating projects.

- Ability to generate precision-coated prototype samples up to six feet long using only a few grams of solution.

- Provides small-scale, roll-to-roll coating for up to 12-inch wide films, foils, paper and membranes, for larger prototype quantity requirements.

- Contains custom mixing, solution delivery, coating, drying and analytical equipment used for small-scale, early-stage product and process development.

- Ability to predict how a given coating solution and substrate system will behave in various manufacturing operations before scaling up to larger pilot-scale and manufacturing-scale equipment.

Pilot Coating:

- Proprietary coating techniques, enhanced drying methods and streamlined solution delivery systems.

- Ability to simultaneously use multiple coating techniques at our different locations to enhance collaboration, execute rapid prototyping and scale-up projects, and troubleshoot issues.

- Pilot coaters modeled after larger coaters to ensure seamless transfers to full-scale manufacturability.

Production Coating:

- Enables mass production of commercial products at minimal cost and reduced time-to-market for customers coating advanced material solutions onto flexible substrates.

Technologies:

Technologies: Pilot Capabilities:

Pilot Capabilities: Solution Making:

Solution Making: On-Line Inspection and Instrumentation:

On-Line Inspection and Instrumentation: Converting:

Converting: Carestream’s highly flexible coating assets, combined with our experienced technical and business teams, enable rapid material and product screening, small product sample coating and testing, and efficient scale-up to pilot and production coating equipment. We work with our partners to quickly adjust formulation and coating conditions for low-cost, small-run and experimental multilayer coating projects.

Carestream’s highly flexible coating assets, combined with our experienced technical and business teams, enable rapid material and product screening, small product sample coating and testing, and efficient scale-up to pilot and production coating equipment. We work with our partners to quickly adjust formulation and coating conditions for low-cost, small-run and experimental multilayer coating projects.